Editor’s column: Optimistic about 2021

The year of 2020, having recently come to its end, certainly appeared to be a big challenge for all of us, including the close-knit ITER community. It would be unfair to claim it had no impact on the ITER Project joint implementation process. Despite that, due to strong enthusiasm and unbreakable devotion of the Unique ITER Team to the goals and values of the common endeavor, as well as constant readiness to keep on the pace with all the available resources, it became possible to bring remarkable progress to the Project.

This also refers to Russia’s industries’ contribution, which manifests itself in developing and fabrication of the machine’s highly sophisticated components. In times of COVID-caused restrictions and limitations, Russian research institutes and production companies continued fulfilling their obligations within the ITER Project to make First Plasma more and more real. The intention not to slow down in 2021 makes it reasonable to feel enthusiasm about this year’s foreseen accomplishments. Most remarkable milestones of the Russian contribution of 2020 – in 2021’s first RFDA ITER Newsletter.

|

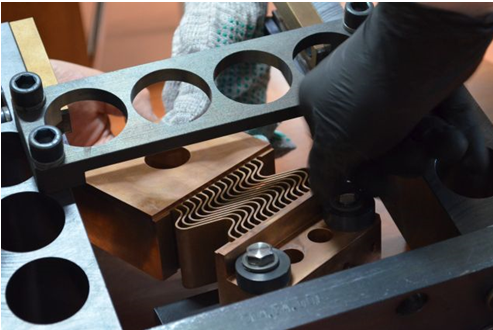

First Wall Pannels - 2020 plan comleted

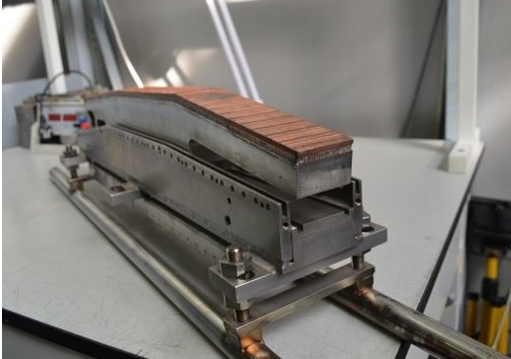

In regard of manufacture of the 179 Enhanced Heat Flux First Wall panels (up to 5MW/m2), within the Russian Federation obligations, the 2020 plan has been completely fulfilled in fabricating beryllium heat-protective tiles. All in all, 13 625 tiles have been produced. 80 casings (four types) of the energy-loaded components (so called “fingers”) and 160 covers of the return channel (four types) for the First Wall full-scale prototype have been manufactured. The works are being carried out in full compliance with the schedule. 2020 milestone has been 100 % completed. |

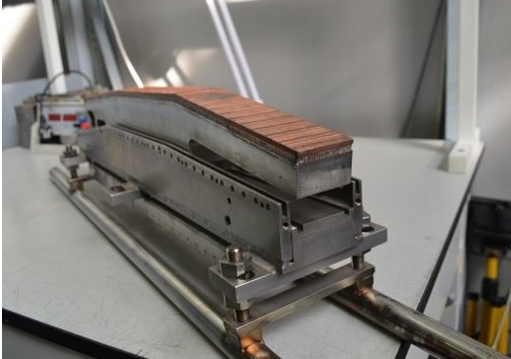

Divertor Dome & High-Heat Flux Tests

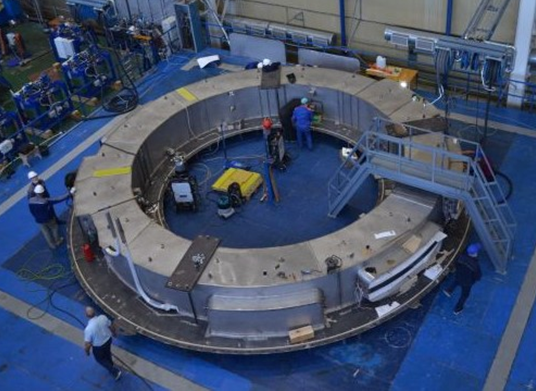

As a reminder, Russia is responsible for manufacture of 58 Divertor Domes and carrying out thermal tests of the in-vessel components, both Russian and foreign. The full-scale prototype of the Divertor Dome is now prepared for transportation to the ITER construction site. Semi-finished elements of the ITER Divertor Dome have been fabricated. Basing on the prototype manufacture experience, design and technological documentation underwent necessary improvement.

In context of High-Heat Flux Tests, the ITER Divertor Test Facility (IDTF, St. Petersburg) has been prepared for testing Dome serial elements, according to the schedule. 300 IUA have been scored by the ITER Organization. |

|

|

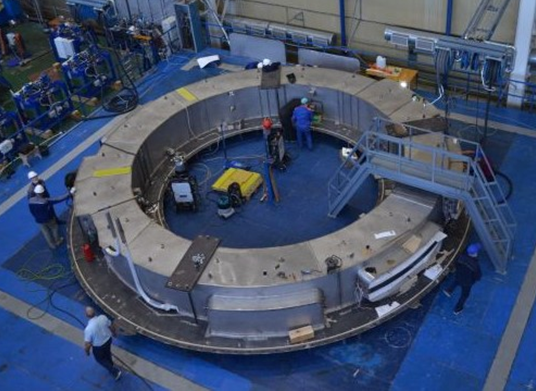

PF1 Coil: approaching the finish line

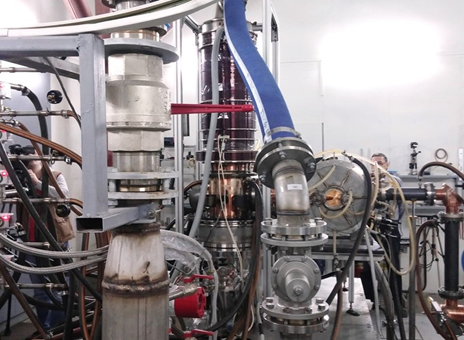

PF1 Coil, one of the six magnets of this kind, is to be located on the very top of the ITER’s poloidal field system. Nine meters in diameter, the 200-tonne superconducting magnet now undergoes final technical operations before shipment to the machine construction site. As for today, the heating system for the Coil impregnation has been tested in the operating modes. Vacuum-related operations have been finished at the manufacturer’s facilities. The installation of the upper cover of the power volume is being prepared. The technology of installing clamps and cryogenic strapping was tested.

In line with the schedule, the PF1 Coil is supposed to be delivered to France by the end of this year. |

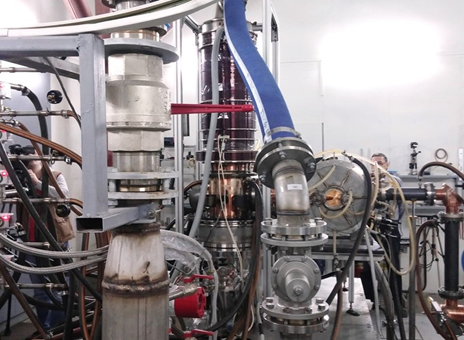

EC Gyrotrons: equator passed

Works on eight Russian Gyrotrons – sophisticated heating and current drive systems – are being carried out steadily. In accordance with the 2020 internal testing program, tests of the fifth Gyrotron have been fully and successfully conducted. Technical commission has accepted all the scheduled works. Factory acceptance tests are scheduled for May 2021. The report materials for the 2020 works have been laid out and accepted. Review and adjustment of the documents referring to the control system of the first Gyrotron pair is ongoing. Auxiliary equipment for 1-4 Gyrotrons is being prepared for delivery to the ITER construction site in 2021. |

|

|

Upper Ports: deliveries underway

Manufacture of the ITER Vacuum Vessel Upper Ports – 18 in total – fully lay within the Russia’s responsibility. For the moment, works on fabricating Upper Ports, including PSE № 01, 07, 13, 15 and 17, as well as PE № 12 and separate elements of PE № 13, 14, 15 have been completed. The Upper Ports PSE № 01 & PSE №13 have been delivered to the ITER Organization Vacuum Vessel assembly facility. Tests of the Upper Ports carried out by the IO have proved compliance with the ITER requirements. Therefore, the 2020 milestone has been 100 % completed.

|

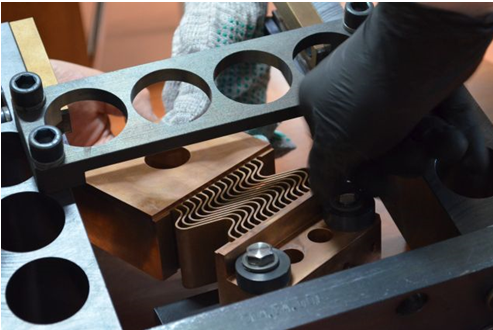

Вlanket Module Connectors

Blanket Module Connectors, manufactured in Russia, are aimed at keeping blanket modules from moving in radial, poloidal and toroidal directions. Manufacture and procurement of the electrical straps pedestals (belong to the ITER in-vessel components) is ongoing. Up to the moment, 142 pedestals have been already accepted by the ITER Organization. The rest pedestals are expected to be delivered to the ITER construction site this year. Pedestals (more than 1000 pieces) are to be installed inside the machine’s vacuum vessel before the First Plasma. |

|

|

First delivery of switching equipment to France

In November 2020, first Russian switching devices (10 in total), along with control systems, for power supply systems of superconducting cols of the ITER electromagnetic system were shipped to the machine’s construction site. These are the first active components that are part of electro-technical equipment, the supply of which is fully entrusted to the Russian Federation. The equipment is designed to protect AC/DC converters in case of emergency and provides shunting of the converter terminals in the event of a failure of the main thyristor bypass device. To date, Russia has already delivered more than a kilometer of busbars, being now installed in the respective buildings. |

MEDIA

Атомная энергия 2.0, 26.11.2020

Атомная энергия 2.0, 26.11.2020

Научная Россия, 01.12.2020

Научная Россия, 01.12.2020 Телеканал Звезда, 23.11.2020

Телеканал Звезда, 23.11.2020